We focus on the cultivation of innovation ability, and actively develop advanced manufacturing technology and apply it to our dryer vent fan, circulan inline duct fan, in-line tube fan. We have formed the ability to plan and run the project as a whole, and at the same time actively play the role of network and enterprise informatization coordination, so as to win the market first with the fastest service speed and ability. Our company based on modern science frontier, product quality inspection process to achieve third-party quality control. We have constructed strong and long co-operation relationship with an enormous quantity of companies overseas.

Product Introduction

The new generation of Lionball ECM products are the motors of high efficiency, comparing to the same kind products. For the size and assembling, it can compatible with shaded pole motor. Many material are available for ECM, such as the plastic, aluminum, and the cast iron. What’s more, the protection grade of ECM reaches IP66 and it is with approvals of VDE, UL, CE, CCC.

1.High efficiency of up to 70%.

2.Constant speed, even in the event of voltage fluctuations.

3.High running smoothness due to ball bearings system.

4.Intelligent electronics with control, overload, and locked-rotor protection.

5.Conventional AC technology can be replaced easily.

6.Available in 24V, 115V and 230V.

7.Control include CW and CCW, double speed, variable speed.

8.Operating temperature : -20℃——50℃.

Product Parameter (specification)

(1)Parameter of function

| Motor | Voltage | Frequency | Current | Speed | Input/Output |

ECM12A110 | 1~110V | 50/60 | 0.25 | 1550 | 22/15 |

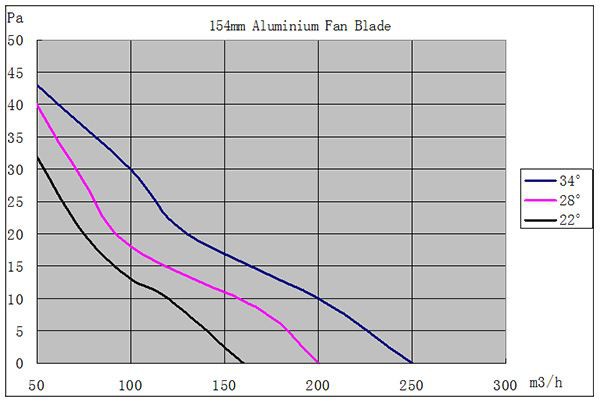

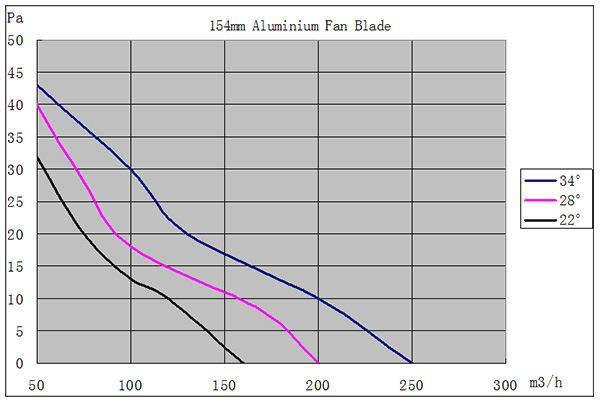

(2)Airflow

| Index | Motor | Axial impeller | Axial impeller | Input |

1 | ECM12 | 200 | 22 | 5.8 |

2 | ECM12 | 200 | 28 | 8.4 |

3 | ECM12 | 200 | 34 | 13.6 |

4 | ECM12 | 230 | 22 | 11.6 |

5 | ECM12 | 230 | 28 | 17.4 |

6 | ECM12 | 254 | 22 | 17.3 |

﹡ Speed = 1550RPM

Product feature and application

(1) Product feature:

●Compact structure

●Higher energy efficiency

●Intelligent protection function

●Product diversification

●Wide range of use

●Reliability

●Lower temperature rise

(2)Application

Supermarket commercial freezers, refrigerator,evaporator, heater, dehumidifier, refrigerating, radiator,welding machine, etc.

Deliver and serving

(1)Deliver

About 30-40 days after receive client’s payment. Because we are manufacturer, and we don’t have production in stock. We will arrange production as soon as possible.

(2)Service

①Pre-sales services:

We have Personalized Customization Scheme for every client.

We will adjust the voltage, frequency, length of line and other detail character according to client’s demand.

②After-sales services

According to the requirements of consumers, carry out the technical guidance on the use and other aspects

Dealing with customers' letters, visits and telephone complaints, answering customers' inquiries. At the same time, we will use various ways to collect the opinions of consumers on the quality of products, and improve them in time according to the situation.

warranty: one year after ETD.

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for Micro DC Motor Electric Drive High Speed Electromagnetic Gear High Quality Phase Scooters Elevator Shaft Engine Drive Best Stepper Synchronous Motors. We have developed a variety of new products that meet market needs and gradually expand the application areas of products. We have always clung to the tenet of seeking development by reputation, survival by quality, and benefiting from management, and we continue to develop with the joint efforts of all employees.

Hot Tags: ec freezer fan motor, China, suppliers, manufacturers, factory, customized, wholesale, price, quotation, pricelist, for sale, Backward Curved Centrifugal Fan, refrigerator condenser fan, backward curved fan, Axial Fan For Air Compressor, EC Centrifugal Fan, duct centrifugal motor