We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for commutated motor, shaded pole fan motor, Small Centrifugal Blower Fans. We always pay attention to market changes and customer needs, devote ourselves to the research and development of new products, new technologies, new techniques and innovation, constantly improve quality, reduce costs and improve services. We have developed rapidly in the market economy. Since the establishment of the company, our products have been produced in strict accordance with international standards. We have won high reputation and market share in the market. We will keep you informed of our progress and look forward to building steady business relations with you. Practical experience tells us that finding demand is the key to product innovation, so that we listen to customer feedback in a timely manner and make improvements.

Production description

YWF series centrifugal fan with external motor has features of compact structure,convenient installation, credible running, little noise, energy saving and high efficiency.

Our product YWFF250 has several speed ranks, adapt to both frequency conversion and voltage transformation speed changing active.

Our products are widely used in refrigeration and ventilation fields, such as condenser’ evaporator, duct fans, ceiling fans.

Voltage and frequency: Single phase motor is 115/220V, 50/60HZ, three phase motor is 380V, 50/60HZ. We can also supply other fan motors with different voltages and frequencies according to clients’ requirement.

The average service life of motors is more than 17500 hours.

(1)Material: Impeller: galvanized sheet steel

Rotor: Coated in black plastic

(2)Bearings: Maintenance- free ball bearings

(3) Direction of rotation: Clockwise, seen on rotor (opposite cable exit), or viewing from inlet

(4)All models have reached UL approval, CE approval and CCC approval

(5)The type of protection is IP54. All models are fitted with an internal Thermal Overload Protection Device

(6)Mounting position: Shaft horizontal or rotor on bottom; rotor on top on request (Any)

(7)Insulation class is class B or class F.

Performance parameters

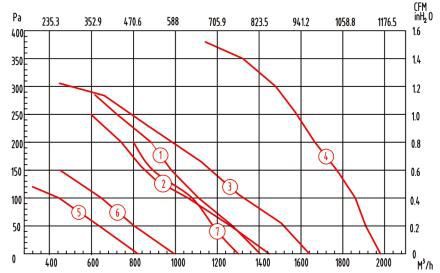

| Model | Voltage | Frequency | Current | Input Power W | Speed | Max Air Flow | Capacitor | Noise dB(A) | Curve | |

YWFB2E250 | 230 | 50/60 | 0.65/0.8 | 145/185 | 2450/2550 | 1400/1450 | 4 | 75/77 | ①② | |

115 | 50/60 | 1.3/1.6 | 145/185 | 2450/2550 | 1400/1450 | 16 | 75/77 | |||

YWFB2E250H | 115 | 50/60 | 2.05/2.9 | 224/330 | 2650/3250 | 1640/1980 | 30 | 80/84 | ③④ | |

YWFB4E250 | 230 | 50/60 | 0.25/0.44 | 48/50 | 1400/1650 | 820/990 | 2 | 61/64 | ⑤⑥ | |

115 | 50/60 | 0.5/0.55 | 48/60 | 1400/1650 | 820/990 | 6 | 61/64 | |||

YWFB2E250P | 230 | 50 | 0.7 | 150 | 2500 | 1300 | 4 | 75 | ⑦ | |

Product feature and application

(1) Product feature:

●Compact structure

●Specialized design

●Refined process control

●Simple Installation

●High efficiency and low noise

●Long service life

(2)Application

Exhausting industrial processes, roof and building ventilation, clean room and other sensitive HEPA filtering application, laboratory and research facility ventilation, air conditioner, heat exchangers, in-line duct blowers, range hood, fire place inserts, humidifiers, dehumidifiers, hand dryers

Production details

Difference between forward centrifugal fan

(1)efficiency: the efficiency of the forward leaning centrifugal fan is lower than that of the backward leaning centrifugal fan.

(2)energy consumption: because the efficiency of the forward leaning centrifugal fan is low, its natural consumption for electric energy is greater than that of the backward leaning type.

(3)noise: when the forward leaning centrifugal fan is in operation, the noise emitted by the forward leaning centrifugal fan is larger than that of the backward leaning fan.

Persisting in 'High quality, Prompt Delivery, Competitive Price', we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for Low Noise High Pressure Industrial Snail Shape Centrifugal Exhaust Blower Fan/Axial Fan/Dedusting Fan/Tunnel Fan/Boiler Fan/Coal Mine Fan From OEM. In recent years, the company has devoted itself to exploring the market and its business has spread all over the country. We believe that employees are the most valuable resources and assets for enterprise development.

Hot Tags: centrifugal bathroom fan, China, suppliers, manufacturers, factory, customized, wholesale, price, quotation, pricelist, for sale, inline duct fan, Electronic Commutation In Bldc Motor, axial fan for air cleaner, boiler centrifugal fan, EC Motor, AC Shaded Pole Motor