Our rigorous quality management, mature and excellent technology, and advanced and complete test methods are reliable guarantees of the quality of our Electronically Commutated Motor ECM, in-line tube fan, Backward Centrifugal Fan. We inspire our employees to strive for enterprising morale and strive to contribute to the innovation and transformation development of the enterprise. Our company adheres to the quality policy of 'product and peer competition, quality in line with international standards' and strive to create our brand.

Production description

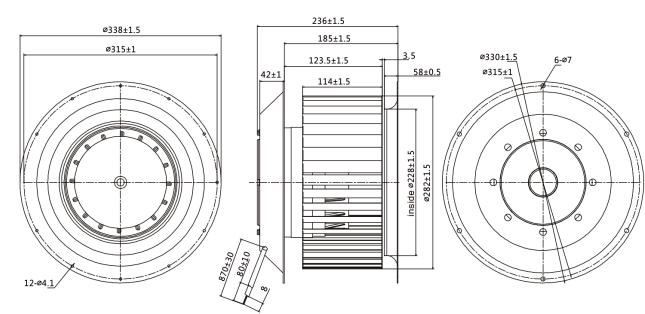

Single Inlet Forward Centrifugal fans and blowers are compact units that can be used to either pressurize or evacuate in air moving applications. The impellers are permanently mounted to the external rotors for ease of installation and maintenance-free operation. These units may be mounted in any orientation to provide maximum airflow in minimum areas.

(1)YWF External Rotor Centrifugal Fans are divided into forward centrifugal fan and backward centrifugal fan according to curved blades, which have compact structure, convenient installation, credible running, little noise, energy saving and high efficiency.

(2) Several speed ranks, adapt to both frequency conversion and voltage transformation speed changing active. Our products are widely used in duct fans, roof ventilator, air purifying equipment, air conditioning, and household appliances, etc.

(3)The voltage of the single phase motor is 220V, 50/60 Hz, and the voltage of three phase motors is 380V, 50/60Hz. We can also supply other fan motors with different voltages and frequencies according to clients' requirement.

(4)The safety grade of this series is IP54, and the insulation classes are class B and class F.

(5) The applicable ambient temperature of the fan motors used in condenser is from -30℃~60℃.

(6)The average service life of motors is over 30,000 hours.

(8) Our products have gotten UL approval, CE approval and CCC approval.

(9) Product Features

① —Material: Housing: galvanized sheet steel

Impeller: galvanized sheet steel

Rotor: Coated in black plastic

② Bearings: Maintenance- free ball bearings

③ Direction of rotation: Clockwise, seen on rotor

④All models have reached UL approval, CE approval and CCC approval

⑤The type of protection is IP54. All models are fitted with an internal Thermal Overload Protection Device

⑥ Mounting position: Shaft horizontal or rotor on bottom; rotor on top on request (Any)

⑦Insulation class is class B or class F

Performance parameters

| Model | V | Frequency | Current | Input Power | Speed | PA | Max Air Flow | Capacitor | Noise | Curve |

YWFF4E280 | 230 | 50 | 5.4 | 1.2 | 1400 | 50 | 3500 | 30 | 76 | ① |

YWFF4D280 | 230△/400Y | 50 | 4.3/2.5 | 1.35 | 1400 | 0 | 3700 | / | 76 | ② |

YWFF6E280 | 230 | 50 | 2 | 0.46 | 900 | 0 | 2400 | 8 | 66 | ③ |

YWFF6D280 | 230△/400Y | 50 | 1.5/0.9 | 0.47 | 900 | 0 | 2400 | / | 66 | ③ |

Product feature and application

(1) Product feature:

●Compact structure

●Specialized design

●Refined process control

●Simple Installation

●High efficiency and low noise

●Long service life

(2)Application

●Condenser

●Evaporator

●Pipe fan

●Roof ventilator

●Heat dissipation and ventilation

Illustration of Models

YWF—F—2—E—200

① ② ③ ④ ⑤

①YWF: External Rotor Centrifugal Fan

②F: Forward

B: Backward

D: Double Inlet

③(2,4,6):Pole of Motor

④E: Single Phase Capacitor Operation

D: Three Phases Asynchronous Operation

⑤200: The Diameter of inlet

The Research and Development Center

The Research and development center of Ningbo Lionball Ventilator Co., Ltd is a national R&D center. It is appraised as High-tech Enterprises and Engineering Technology Center and has obtained many important prizes in the provincial projects.

Research and development center currently has 25 staff members. We introduced Germanic technology and employed a well-paid fan expert as our technical adviser. What is more, we have cooperated with international renowned enterprise EMERSON for about 5 years and will hand in hand with Carrier China.

Research and development center are facilitated with modern equipment and advanced laboratories: Air flow laboratory and life testing laboratory. We provide each member with professional inspection equipment for better research environment.

Over the past two years, owing to continuous effort of R&D team, we have successively obtained 15 certificates of Utility Model patent and 2 certificates of Invention Patents.

(1)Our Certificates of Utility Model Patent

(2)Certificates of Invention Patent

We have a rich and complete management and manufacturing system, advanced production equipment and technology, and a standardized and excellent production environment for professional manufacturing of high-quality Hot Sale Large Power Screw Air Compressor (SCR270II SERIES) with High Quality German Centrifugal Fans Air Filter System and other product services. We are in the pursuit of excellent product quality and brand at the same time, in line with the enterprise tenet of 'good faith management, build brand', unremitting efforts, all-round to meet the needs of customers and partners. We will adhere to 'high standards and strict requirements' as in the past, we are willing to seek win-win business cooperation with customers like you with professionalism and integrity.

Hot Tags: centrifugal fan for industrial refrigeration system, China, suppliers, manufacturers, factory, customized, wholesale, price, quotation, pricelist, for sale, Electeical Comutation, axial fan for freezing chamber, Centrifugal Fan For Air Filtration Equipment, UL Approval Steel Type Circular Duct Fan CDF Serie, Centrifugal Blower Fan, shaded pole ac motor