We simplify the product development process, shorten the product development cycle, reduce product development costs and costs, significantly improve product quality, improve product system performance, and obtain optimized and innovative ec duct fan, EC Centrifugal Fan For Air Filtration Equipment, Backward Centrifugal Fan For Hutch. Our corporate culture is composed of responsibility, integrity, passion, dedication, aggressiveness and coexistence. We rely on resources advantages, fully grasp the market demand, the use of modern theory and technology, to achieve large-scale development. We have been meeting the expectations of our customers and social needs as our basis, constantly improving our strength and continuing development. Through the establishment of scientific and socialized talent evaluation mechanism, we can comprehensively improve the overall quality of enterprise talent team and broaden the channels of talent introduction.

Type | Aluminum double feet Unit bearing motor |

Shaft | ¼” x 20 thread standard, Optional features include flatted end, smooth end, 5/16″diameter shaft. And rear shaft extension. |

Material | Aluminum |

Bearing | Unit bearing |

Mounting | Five .150” diameter cored holes on rear (aluminum), three #8-36 drilled through and tapped (cast iron), and optional 2 side mounting bosses for pedestal mounting |

Operating Position | Horizontal shaft (+/- 15°), optional all-angle, or vertical shaft up |

Leads | Standard 18 gauge, 2 conductor. Lead cord may be terminated with 1/2” stripped wire, in-house molded plugs, eyelets, ¼” quick connects, or special terminals. Other customized lead options are available. |

Rotation | Clockwise as viewed from back or lead end of motor. Counter clockwise is available to meet client’s requirements. |

Approvals | UL approval(E256488 and E221116), SASO approval |

Operating temperature | -20℃ to 50℃ |

Service life | More than 60000 hours |

Performance parameter

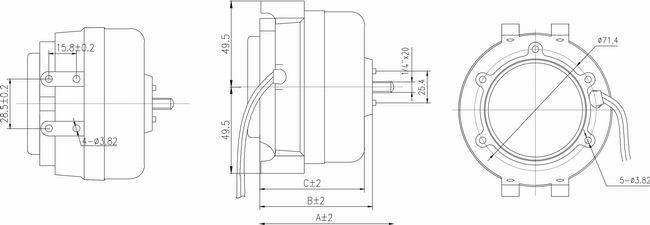

| MODEL | VOLTAGE V | FREQUENCY | OUTPUT | CURRENT A | SPEED | ROTATION | A | B mm | C mm |

YJ2-115-A21 | 115 | 50/60 | 2 | 0.28 | 1300/1550 | CW | 76 | 66 | 61 |

YJ2-115-A22 | 115 | 50/60 | 2 | 0.28 | 1300/1550 | CCW | |||

YJ2-230-A21 | 230 | 50/60 | 2 | 0.14 | 1300/1550 | CW | |||

YJ2-230-A22 | 230 | 50/60 | 2 | 0.14 | 1300/1550 | CCW | |||

YJ4-115-A21 | 115 | 50/60 | 4 | 0.32 | 1300/1550 | CW | |||

YJ4-115-A22 | 115 | 50/60 | 4 | 0.32 | 1300/1550 | CCW | |||

YJ4-230-A21 | 230 | 50/60 | 4 | 0.16 | 1300/1550 | CW | |||

YJ4-230-A22 | 230 | 50/60 | 4 | 0.16 | 1300/1550 | CCW | |||

YJ5-115-A21 | 115 | 50/60 | 5 | 0.36 | 1300/1550 | CW | |||

YJ5-115-A22 | 115 | 50/60 | 5 | 0.36 | 1300/1550 | CCW | |||

YJ5-230-A21 | 230 | 50/60 | 5 | 0.18 | 1300/1550 | CW | |||

YJ5-230-A22 | 230 | 50/60 | 5 | 0.18 | 1300/1550 | CCW | |||

YJ6-115-A21 | 115 | 50/60 | 6 | 0.43 | 1300/1550 | CW | 85 | 74 | 69 |

YJ6-115-A22 | 115 | 50/60 | 6 | 0.43 | 1300/1550 | CCW | |||

YJ6-230-A21 | 230 | 50/60 | 6 | 0.2 | 1300/1550 | CW | |||

YJ6-230-A22 | 230 | 50/60 | 6 | 0.2 | 1300/1550 | CCW | |||

YJ9-115-A21 | 115 | 50/60 | 9 | 0.64 | 1300/1550 | CW | |||

YJ9-115-A22 | 115 | 50/60 | 9 | 0.64 | 1300/1550 | CCW | |||

YJ9-230-A21 | 230 | 50/60 | 9 | 0.32 | 1300/1550 | CW | |||

YJ9-230-A22 | 230 | 50/60 | 9 | 0.32 | 1300/1550 | CCW | |||

YJ14-115-A21 | 115 | 50/60 | 14 | 0.48 | 1300/1550 | CW | |||

YJ14-115-A22 | 115 | 50/60 | 14 | 0.48 | 1300/1550 | CCW | |||

YJ14-230-A21 | 230 | 50/60 | 14 | 0.21 | 1300/1550 | CW | |||

YJ14-230-A22 | 230 | 50/60 | 14 | 0.21 | 1300/1550 | CCW | |||

YJ16-115-A21 | 115 | 50/60 | 16 | 0.92 | 1300/1550 | CW | 95 | 83 | 78 |

YJ16-115-A22 | 115 | 50/60 | 16 | 0.92 | 1300/1550 | CCW | |||

YJ16-230-A21 | 230 | 50/60 | 16 | 0.48 | 1300/1550 | CW | |||

YJ16-230-A22 | 230 | 50/60 | 16 | 0.48 | 1300/1550 | CCW |

Product feature and application

(1) Product feature:

●Reliability

●Diversification of installation

●Specialized structure design

●A wide range of applications

●low noise

●Long service life

(2)Application

Our cast iron double feet unit bearing motors are primarily used in commercial refrigeration, condensing unit and unit heater, ice machine. They can be used in many applications demanding high efficiency and dependability with output ratings between 2-16 watts.

Prodection details

Advantage of unit bearing motor

YJ series unit bearing motor with single phase, 4 shaded poles are running at rated voltage of 230V,115V, 127V,Frequency is 50/60Hz.

These motors will fit existing brackets used by GE, Morrill and A.O.Smith designed for quiet, efficient fan duty operation. The unit bearing motor significantly outperforms traditional shaded pole motor. With efficiencies three times higher than shaded pole motors, in addition to the reliable and quiet unit bearing design, our company provides users the most reliable and best energy savings solution for their applications.

All of our unit bearing motors will match with a variety of mounting brackets and fan blades in order to optimize airflow and system efficiency.

The motors can be protected with thermal protection in accordance with client’s request. When the temperature of winding is at 125℃±5℃, the thermal protector will cut off the current.

We ensure that the safety, reliability and applicability of all Best Quality Axial Universal Electric Fan Motor for Air Cooler designed and manufactured meet the standard requirements. Our company has accumulated rich production experience, using advanced equipment, high-standard materials and fine craftsmanship to continuously improve product quality and strive to achieve zero defects in product quality. Our technology focuses on maturity, feasibility, operational efficiency, enterprise scalability, business continuity, international scope and management issues.

Hot Tags: unit bearing motors for cake cabinet, China, suppliers, manufacturers, factory, customized, wholesale, price, quotation, pricelist, for sale, 4 inch exhaust fan, in line duct fan, DC Centrifugal Direct Drive Fan, EC Centrifugal Fan For Dust Collecting Unit, Backward Centrifugal Fan For Hutch Defends The Fan, Axial Fan For Condensing Unit