Our Centrifugal Bathroom Fan, hvac booster fan, Electronic Commutation In Bldc Motor are innovative and practical, meeting the needs of different markets at home and abroad, with broad application prospects. The company adheres to the quality policy of "Quality First, Customer Satisfaction" as its service tenet, gathers the strengths of hundreds of families, strives for excellence, treats people with sincerity, seeks development in competition, seeks leadership in technology, seeks perfection in service, and cooperates with the general public. Users work together to create a brilliant future. We respond to the changes in the internal and external competitive environment of the company, change the rough human resource management to refinement, so as to attract more excellent talents for the company. Many enterprises are having great impact on the world and we believe that we are.

Single Inlet Forward Centrifugal fans and blowers are compact units that can be used to either pressurize or evacuate in air moving applications. The impellers are permanently mounted to the external rotors for ease of installation and maintenance-free operation. These units may be mounted in any orientation to provide maximum airflow in minimum areas.

Forward centrifugal blowers always require scroll housing, which is open on one side. The characteristic features of this product series are high efficiency, a low noise level, relatively small air flow with a high increase in static pressure, robust design and space-saving application.

| The diameter of Impeller | 160mm | |

Material | Housing | galvanized sheet steel |

Impeller | galvanized sheet steel | |

Rotor | Coated in black plastic | |

Direction of rotation | Clockwise, seen on rotor | |

Counter-Clockwise, seen on rotor | ||

Type of protection | IP54 | |

Insulation class | Class B or Class F | |

Mounting position | Shaft horizontal or rotor on bottom; rotor on top on request(Any) | |

Condensate discharges | Rotor-side | |

Approvals | CE, CCC,UL and so on | |

Mode of operation | Continuous operation(S1) | |

Bearings | Maintenance- free ball bearings | |

Motor protection | TOP wired internally | |

Cable exit | variable, lateral | |

Ambient temperature | -20℃ to 60℃ | |

Advantage | YWF series centrifugal fan with external motor has features of compact structure,convenient installation, credible running, little noise, energy saving and high efficiency. | |

Performance parameters

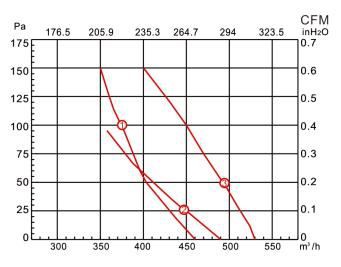

| Model | Voltage | Frequency | Current | Input Power | Speed | Max Air Flow | Capacitor | Noise | Curve |

YWFF2E160 | 230 | 50 | 1.2 | 280 | 2000 | 630 | 8 | 72 | ① |

YWFF4E160 | 230 | 50 | 0.37 | 84 | 1280 | 490 | 2.5 | 66 | ② |

115 | 60 | 0.95 | 110 | 1340 | 530 | 10 | 68 | ③ |

Product feature and application

(1) Product feature:

●Compact structure

●Specialized design

●Refined process control

●Simple Installation

●High efficiency and low noise

●Long service life

(2)Application

●Condenser

●Evaporator

●Pipe fan

●Roof ventilator

●Heat dissipation and ventilation

Illustration of Models

YWF—F—2—E—200

① ② ③ ④ ⑤

①YWF: External Rotor Centrifugal Fan

②F: Forward

B: Backward

D: Double Inlet

③(2,4,6):Pole of Motor

④E: Single Phase Capacitor Operation

D: Three Phases Asynchronous Operation

⑤200: The Diameter of inlet

Our company keeps up with the trend of the times and launches novel series of 4-68 Snail Shape Air Circulation Industrial Dust Collector Small Centrifugal Fan&Blower with powerful functions to bring convenience to production. In the future, our company will continue to improve the production process and improve the management system with high standards. We should cooperate with other companies to complement each other's advantages in order to strengthen our competitiveness together, and therefore adapt to the competitive environment of the contemporary market.

Hot Tags: small centrifugal blower fans, China, suppliers, manufacturers, factory, customized, wholesale, price, quotation, pricelist, for sale, Forward Centrifugal Fan, Centrifugal Fan For Air Filtration Equipment, in line duct fan, Backward Curved Centrifugal Fan, working of shaded pole motor, Refrigeration Unit Bearing Motor